RV 14 Build September 13 & 17

Aft Fuselage

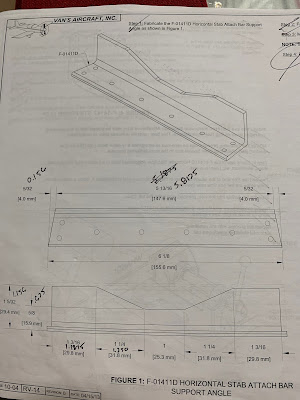

My replacement horizontal stab attach bar support angle showed up and I was able to get it cut, prepped and primed on the first day of work.

This is the plans for the rework.

I have a better understanding of what the angle does and where it sits, it definitely helped in the fabrication knowing how it will be used.

Overall Im happier with this version of the support angle than the first, I did have to go back and hit it with a little more primer after it was done drying I noticed my coverage on part wasnt great.

Getting ready to match drill the hole that I messed up the first time around.

Match drilling successful this time!

Pretending to rivet for the Camera lol

Done! And this completes Section 10: Aft Fuselage

This is the plans for the rework.

Overall Im happier with this version of the support angle than the first, I did have to go back and hit it with a little more primer after it was done drying I noticed my coverage on part wasnt great.

Time to work the install!

Getting ready to match drill the hole that I messed up the first time around.

Match drilling successful this time!

Pretending to rivet for the Camera lol

Done! And this completes Section 10: Aft Fuselage

Aft Fuselage Hours 4.0