RV14 Build May 21

Cowling

First thing you need to do is level the airplane. I checked it at several areas but thing the spar is probably the most accurate.

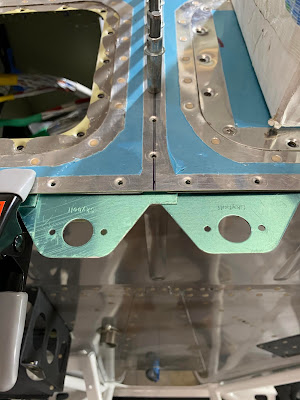

Finally have a 3/16 gap at the bottom edge.

I noticed the cowling isn't sitting flush and it looks like the honeycomb is interfering with the skybolt and had to be shaved.

I marked the interference with a sharpie and started to sand.

Cutting back the honeycomb.

These are the magnetic hole finders for skybolt. Little magnet at the bottom and a chamfered hole to help guide the drill bit.

Magnet hole finders.

Little metal ball showing the hole center.

Dilling, clekoing, and praying.

Step drilling the final hole size. Most of my center hole drills were not exact and in the end it pulled the front cowling forward about 1/32 of an inch.

Installing the skybolt locks.

You install these and then spin them up or down as needed then pull the little round pin in the lower right of the circle to lock the distance. This accommodates different cowling thicknesses.

Skybolt installed and locked. Getting here feels like it takes forever on the cowling work.

Glad I did turned out much better.

Making sure the bottom cowling trim fits.

Lining up the hinges for drilling.

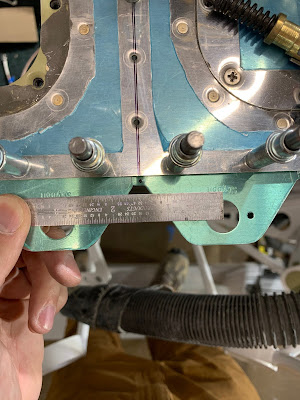

Using the measurements from the book and the rivet spacer to drill the holes.

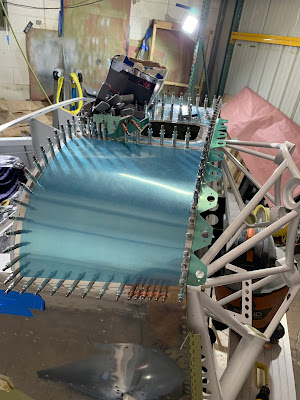

Lower cowling hinges all drilled.

Cowling hinges all drilled!

Had to put some wood under the right main, turns out my shop floor isn't level. Maybe that's why when I drop things they magically disappear forever never to be seen again lol.

Getting the angle on the front of the cowling in the center. I thought finding the exact center was super important, but turns out not so much.

To get the cowling to fit at all I had to sand the aft edge down. Use the long sanding block to try and keep it even.

Got the cowling to fit in there, now time to sand and re-fit about 1000 times to get the correct gap.

I used my laser range finder set on the level to measure the edge distance of the cowling to make sure it was centered why I was sanding to fit. The laser worked well and the amount of times I took the cowling off to trim made re centering much faster.

I marked the interference with a sharpie and started to sand.

Test fitting the lower cowl for trimming.

Trimmed the lower cowling. My trimming of the top wasn't great so I really had to talk myself into trusting my markings.

marking the rivet lines.

Holding the bottom cowling tight as possible without warping it and drilling the rivet holes for the hinge.

Hinge is drilled and upper cowl is used as a cutting template for the lower.

Using a feeler gauge to find interference and trim the lower cowling to fit just right.

the long side hinge pin is supposed to rest on top of the vertical pins, but the vertical sat too high so I trimmed the eyelet.

All good now

Using the rivet spacer and measurements to drillth top cowling. I wish I would have transferred the rivet hole lines as well from the bottom. My holes are just slightly off center of the bottom cowling.

Next I mixed up some epoxy with white tint and covered the cowlings inside. I ended up putting 3 layers on to make sure I had good coverage.

Installing the lower cowl heat shield

Third times a charm..

Cowling 48.5 Hours