RV14 Build Rest of December

FWD MID FUSE Side Structure

This is half of Januarys work to wrap up section 29, it felt like it would never end! On the last post Travis and I got the left side skin clekoed in place and ready to rivet. Most of this month i worked without help so a lot of prep, deburring, and priming to get ready for several big days of riveting.

Started out with a bang, mocking up the right side and countersinking the center section plate...on the wrong side! New parts on order, as well as some more fuel line, ill get to that in post on section 31.

Hard to see in the picture, but the part is oriented backwards and the top left hole are countersunk on the wrong side.

Liz came to the shop to help!!

I am really bad at tacking "as I go pictures" when I have someone in the shop helping me. These are the first rivets the Liz helped me install!

Primed the right side skin

Back in the shop alone and riveting the internal fuselage structure. Im able to reach both sides fairly well. Definitely move slower when riveting alone.

I didn't show it, but while I was priming this Liz was scuffing the other side and its parts for topcoat later. This time I got smart and scuffed everything before dimpling to make it easier on the scotch-brite bad.

Still working solo to I looked ahead in the plans and pulled the rest of the parts for section 29, all the parts of section 30 and some of the brackets for 36. Before joining the section 29 to the empennage it seems to make sense to work ahead and install as much as possible while the access is better.

Replacement center section is in.

Match drill with the old on, and countersink....This time on the correct side! I checked like 10 times to make sure!

Finally ran out of my AKZO primer, had to finish the last few pieces with SEM self etching. I definitely wasted too much by over spraying and poor mixing techniques in the beginning. Aircraft Spruce has been out of stock for several months, but luckily I found a place local-ish that has it in stock and Im gonna be around this week to pick it up.

The seat back rest in the plans for some reason looks intimidating! There is a lot of instruction on 1 page, but taking it in small steps I was able to get part buit.

The spacer leave a gap so the seat back will slid into it....I think lol

Just missing the counter sunk edge pieces. I had some question about the degree of a AN rivet. It turns out the are 100 or my standard countersink cutter worked for the ACQ counter sunk pop rivets that the plans called specifically to cut at 100 degrees.

This was a huge messy day that I took almost no pictures for. Matt is back in the shop and we finished riveting on the left skin, riveted on the right and pro-sealed the front and top of the skin, then riveted.

You can see a little of the pro-seal on the longeron before we got it all cleaned up after riveting.

Done wit the pro seal, I looked ahead on the planes and found a fuel system and brake system part that pass through the firewall that needed to be sealed too, so I installed those now to save on wasting a tube of pro seal on them later. After talking to some guys, probably could just use Alex Plus from Home Depot instead of proseal for this job.

Starting to look like and airplane......or conoe if you ask Liz!

Installing the rest of the interior braces and covers.

I thought all these holes where suppose to wait for the flap bracket

Turns out its just the side ones, and I missed a dimple!

Luckily the dimpler fits in the flap bracket hole!!

Flap bracket installed

The next day after I cleaned up the rest of the pro seal I noticed that the cowling mounting hinge didn't rivet on well. I tried to replace one of them, but it did more harm than good. I think the rivets might be stronger than the hinge? So when they set on an angle they dug into the metal. Since access to this area is always good Im going to leave it alone for now and if the rivets cause issues in the future I will drill a new hinge and replace it.

Installing the seal back and gusset roll over brace

More of the seat back and gusset

Ooops! I countersunk the rivets in the red circle too...Vans says no problem, build on!

Felling good and goofing around!

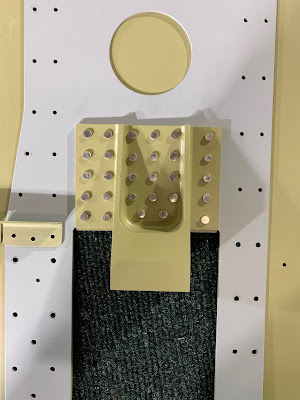

Getting one of the rivets on the gusset to the upper longeron was tricky I had to make this custom bucking bar

feeling good about this outside the box work lol

Gusset and roll bar base install and torqued

We are basically done with section 29, there are the air vents to go but the plans say to wait until section 35 for clearance issues. We pulled the empennage down from storage and this rivet had been keeping me up at night lol. If you look closely you can see its the metal is not dimpled but its mated to a dimpled surface. I wasn't too concerned with this until I realized it was part of a larger plans change to stop the bottom skin from cracking. Vans says this is perfectly serviceable and the main change was to go to the continuous stringer that its rivets too. Should have asked them months ago so I would stop thinking about it!

A few victory glamour shots!

Hard to see in the picture, but the part is oriented backwards and the top left hole are countersunk on the wrong side.

Liz came to the shop to help!!

I am really bad at tacking "as I go pictures" when I have someone in the shop helping me. These are the first rivets the Liz helped me install!

Primed the right side skin

Back in the shop alone and riveting the internal fuselage structure. Im able to reach both sides fairly well. Definitely move slower when riveting alone.

I didn't show it, but while I was priming this Liz was scuffing the other side and its parts for topcoat later. This time I got smart and scuffed everything before dimpling to make it easier on the scotch-brite bad.

Still working solo to I looked ahead in the plans and pulled the rest of the parts for section 29, all the parts of section 30 and some of the brackets for 36. Before joining the section 29 to the empennage it seems to make sense to work ahead and install as much as possible while the access is better.

Replacement center section is in.

Match drill with the old on, and countersink....This time on the correct side! I checked like 10 times to make sure!

Finally ran out of my AKZO primer, had to finish the last few pieces with SEM self etching. I definitely wasted too much by over spraying and poor mixing techniques in the beginning. Aircraft Spruce has been out of stock for several months, but luckily I found a place local-ish that has it in stock and Im gonna be around this week to pick it up.

Before I found the local shop for the AKZO I ordered my top coat from Stewart and I figured I should order primer just in case I can't replace the AKZO.

The seat back rest in the plans for some reason looks intimidating! There is a lot of instruction on 1 page, but taking it in small steps I was able to get part buit.

The spacer leave a gap so the seat back will slid into it....I think lol

Just missing the counter sunk edge pieces. I had some question about the degree of a AN rivet. It turns out the are 100 or my standard countersink cutter worked for the ACQ counter sunk pop rivets that the plans called specifically to cut at 100 degrees.

Prepping the right side skin to go on.

Back riveted the center section side plate on this side...Wish i would have done that on the other side, the skin looks so much better.

This was a huge messy day that I took almost no pictures for. Matt is back in the shop and we finished riveting on the left skin, riveted on the right and pro-sealed the front and top of the skin, then riveted.

You can see a little of the pro-seal on the longeron before we got it all cleaned up after riveting.

Done wit the pro seal, I looked ahead on the planes and found a fuel system and brake system part that pass through the firewall that needed to be sealed too, so I installed those now to save on wasting a tube of pro seal on them later. After talking to some guys, probably could just use Alex Plus from Home Depot instead of proseal for this job.

Starting to look like and airplane......or conoe if you ask Liz!

Installing the rest of the interior braces and covers.

I thought all these holes where suppose to wait for the flap bracket

Turns out its just the side ones, and I missed a dimple!

Luckily the dimpler fits in the flap bracket hole!!

Flap bracket installed

The next day after I cleaned up the rest of the pro seal I noticed that the cowling mounting hinge didn't rivet on well. I tried to replace one of them, but it did more harm than good. I think the rivets might be stronger than the hinge? So when they set on an angle they dug into the metal. Since access to this area is always good Im going to leave it alone for now and if the rivets cause issues in the future I will drill a new hinge and replace it.

Installing the seal back and gusset roll over brace

More of the seat back and gusset

Ooops! I countersunk the rivets in the red circle too...Vans says no problem, build on!

Felling good and goofing around!

Getting one of the rivets on the gusset to the upper longeron was tricky I had to make this custom bucking bar

feeling good about this outside the box work lol

Gusset and roll bar base install and torqued

We are basically done with section 29, there are the air vents to go but the plans say to wait until section 35 for clearance issues. We pulled the empennage down from storage and this rivet had been keeping me up at night lol. If you look closely you can see its the metal is not dimpled but its mated to a dimpled surface. I wasn't too concerned with this until I realized it was part of a larger plans change to stop the bottom skin from cracking. Vans says this is perfectly serviceable and the main change was to go to the continuous stringer that its rivets too. Should have asked them months ago so I would stop thinking about it!

A few victory glamour shots!

FWD MID FUSE Side Structure 56.5 Man Hours