I spent the first part of the day reworking the spar on the rudder that I had previously drilled the wrong holes in. In the picture below I drilled the white brackets to spar attaching holes to a #12 and they should only be #30.

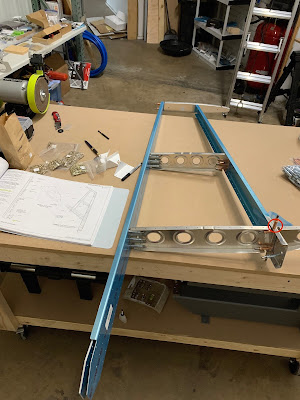

This is what that spar should have ended up looking like with the brackets and the double attached.

After I finished drilling and putting together the spar I took apart the Vertical Stabilizer and installed the new spar to match drill the holes. I am still waiting on the smaller front spar replacement and should have waited putting the skin back on to match drill I think. The nose on the leading edge ribs digs into the inside of the skin each time I try to maneuver the skin into place. Ill have to work out the scratches before priming the skins.

After I reached a stopping point because Im still waiting on parts I turned my attention to the Rudder. The Rudder has a counter balance weight, E614, that needed to be countersunk and the R-912 Rib needed to be dimpled so I started with that. I haven't used my countersink cutters yet so there was a small learning curve to figure out how to get the depth set correctly. Mostly cut, check, readjust, cut more, repeat. This was one of the things I took a video of, so hopefully I can get it processed and put up.

Somehow I managed to loose 1 of the AN5909-10R16 bolts, I really don't want to order a new one because it has to be in the shop.....I think. I assembled the Rudder support brackets and matched drilled next.

After I got all the parts installed that I had prepped and noticed I was missing the top 2 support brackets! I went to the parts rack and there they were, but I ran out of time and had to head home. Next week Ill cut debur and install them.

Vertical Stabilizer 2.0 Hours, Rudder 3.0 Hours