RV14 Build July and August

Outboard Leading Edge

This section doesn't look like it should be much work, but I am making it way harder than it needs to be. Because I was sloppy and have had to redo work.

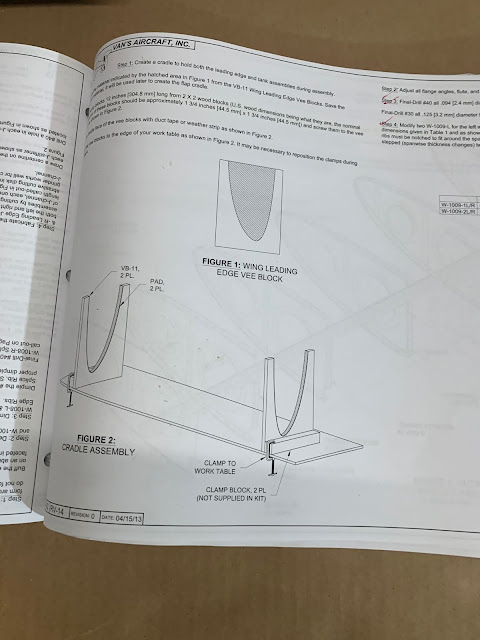

The plans start with making cradles for the leading edge. I knew i was going to take the tanks off so I went ahead and made these.

I cut the cradles from the top lid of the shipping crate from vans, and use a length of 2x4 as a leg brace.

Fuel tanks off the wings and into the newly made cradles. Taking these tanks off was incredibly hard. The amount of force it took to remove the 50+ screws on each tank left a bruise in my hand and I still stripped a few and have to order replacements.

After the cradles the plans have you cut the slot for the stall warning. The skin has 2 small holes that you enlarge, then remove the material in the middle.

Fuel tanks off the wings and into the newly made cradles. Taking these tanks off was incredibly hard. The amount of force it took to remove the 50+ screws on each tank left a bruise in my hand and I still stripped a few and have to order replacements.

After the cradles the plans have you cut the slot for the stall warning. The skin has 2 small holes that you enlarge, then remove the material in the middle.

Stall warning opening.

Stall warning opening.Putting the stall warning assembly together was a little challenging as there are a lot of little bits of hardware.

Countersinking where needed.

Pictures of it all together before priming the metal.

After test fitting I had to bend the sensors tab to get the stall warning vain to have the correct orientation per the plans.

After priming, reassembly and install. This was actually several days later. I was missing a washer that went with the screws to mount into the nutplate.

Nice looking stall warning vain.

Next I started to work on the brackets for the access panel and the landing lights. I went off plans for the landing lights and went with the FlyLeds so this required some modification of the bracket that came in the landing light kit.

Next I started to work on the brackets for the access panel and the landing lights. I went off plans for the landing lights and went with the FlyLeds so this required some modification of the bracket that came in the landing light kit.I didn't need to do and work on the mount brackets and landing light lense backing plates other than dimple and nutplates, so they all were primed in the large batch of parts I did in the beginning. I used a rustoleum flat black, this comes back to haunt me later.

Landing light lense backing plates Since I have different landing light I needed to modify the mounting bracket, so I needed to know how big a hole I will need.

Since I have different landing light I needed to modify the mounting bracket, so I needed to know how big a hole I will need.

Then I primed and "topcoated" the landing light hole in the wings. This is where things went a little south. I used the wrong size squeeze dimpler, and when I re-squeezed the dimples the black started to crack and i noticed it was bubbled up in other areas. Bad surface prep.

Then I primed and "topcoated" the landing light hole in the wings. This is where things went a little south. I used the wrong size squeeze dimpler, and when I re-squeezed the dimples the black started to crack and i noticed it was bubbled up in other areas. Bad surface prep. All Dimpled.

All Dimpled.Re-primes with the SEM gray rattle can, I ordered Tempo Aircraft enamel black from Aircraft Spruce to try for the black this time.

You can see some cracking on the edges, I was lucky and this was all removed in the final trimming.

The scothbrite wheel did a nice job of removing material.

Dremel router bit for getting close on the final cut then back to the scotch brite wheel.

Dremel router bit for getting close on the final cut then back to the scotch brite wheel.

Countersinking, start by hand get close with the cutter, finish by hand.

Chamfering the edges.

Hoving on to the access hatch. I decided I want to prep this for ER tanks in the future, so I need an access panel on both wings and only the left comes with one. I used the doubler and panel to make the template and cut the hole in the right wing. I ordered an additional doubler and panel.

Hoving on to the access hatch. I decided I want to prep this for ER tanks in the future, so I need an access panel on both wings and only the left comes with one. I used the doubler and panel to make the template and cut the hole in the right wing. I ordered an additional doubler and panel.

For the time I moved on to the landing light lenses. First you trace the lenses and do a rough cut. Then you use the backing plates to measure and and do a final cut, debur the holes, chamfer the edges, pilot drill, use double sided tape to mount the backing plates, and final drill.

You can see some cracking on the edges, I was lucky and this was all removed in the final trimming.

The scothbrite wheel did a nice job of removing material.

Dremel router bit for getting close on the final cut then back to the scotch brite wheel.

Dremel router bit for getting close on the final cut then back to the scotch brite wheel.Countersinking, start by hand get close with the cutter, finish by hand.

Chamfering the edges.

Hoving on to the access hatch. I decided I want to prep this for ER tanks in the future, so I need an access panel on both wings and only the left comes with one. I used the doubler and panel to make the template and cut the hole in the right wing. I ordered an additional doubler and panel.

Hoving on to the access hatch. I decided I want to prep this for ER tanks in the future, so I need an access panel on both wings and only the left comes with one. I used the doubler and panel to make the template and cut the hole in the right wing. I ordered an additional doubler and panel.Dimpling and adding nut plates.

Then I used the nibbler to cut away the material.

Flipped the doubler and panel into the hole and used it as a template for the backing plate rivet holes.

Flipped the doubler and panel into the hole and used it as a template for the backing plate rivet holes. Final hole, just needs to be dimpled.

Final hole, just needs to be dimpled.

Using the panel as a template.

I drew the X to try and find the middle of the corners and measures in .250" and drilled a pilot hole.

Opened the corners with the step drill to .5"Then I used the nibbler to cut away the material.

Flipped the doubler and panel into the hole and used it as a template for the backing plate rivet holes.

Flipped the doubler and panel into the hole and used it as a template for the backing plate rivet holes. Final hole, just needs to be dimpled.

Final hole, just needs to be dimpled.

Outboard Leading Edge QBW 28.5 Man Hours