This is my journey to build an Vans RV14 from plans. With the exception that I have later decided to order the RV14 Quick Build Wing. Building mostly alone I was worried about riveting well do to the large size of the wings.

Labels

13-16QBW

21-22QBW

Access Panel Installation

Aft Fuselage

Aft Fuselage Attachment

Aileron & Elevator Systems

Aileron Actuation

Aircraft Specialty

Antenna

Antisplat

Attachment

Avionics

Avionics Panel

B&C Filter

Baffle

Baggage Area

Bottom Wing Skins

Canopy and Window

Canopy harness

Common Fuselage Harness

Control Cables

Cowling

Deydrator

EICAD

Electrical

Eletric Aileron Trim

Elevator

ELT

Empennage

Empennage Fairings

Engine Installation

Exhaust

Exp119 Mods

finishing kit

Firewall

Flap Actuation System

Flap Position Sensor

Fuel and Oil System

Fuel System

Fuel Tank repair

Fuel Tanks

Fuselage

FWD Fuselage Lower Structure

FWD MID FUSE Side Structure

FWD MID Fuselage Bulkheads

FWF

GAP 26

Garmin AutoPilot Servos

Horizontal Stabilizer

Interior Topcoat

Landing Gear & Engine Mount

MID Fuselage Lower Structure

Miscellanea

Move

OP62

Outboard Leading Edge

Paint

parking brake

PitoStatic

Programming

QBW

QBW Corrosion

QBW Re-Work

Reiff

Roll Over Structure

Rudder

Rudder & Brake System

seatback's

shop

Skybolt

Spinner and Propeller

Testing

Upper FWD Fuselage

Vertical Stabilizer

Wheel Fairings

Wing Attachment

Wing Rebuild

Wing Systems Routing

Wing Tip

Wiring

Wednesday, October 2, 2019

Attachment of the Empennage components

RV14 Build September 23 & 25

Attachment

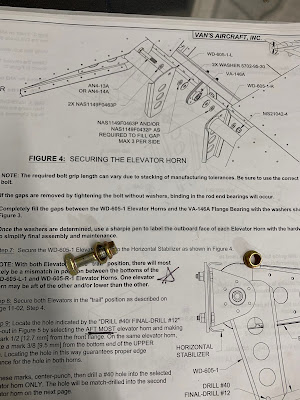

Finishing up the attachment, I have to mount the right elevator and drill the elevator horns, mount the horizontal stab and final drill the rear spar to attachment brackets, install the horizontal stab, mount the rudder and check all the clearances! Time to work.

Using my new toy to check the degrees of deflection to make sure I have a full range of motion. I did have trouble with the elevator leading edges rubbing on both right and left. I had in take them off message the leading edge shape and re-install a few times before it was right.

I didn't get a picture of it but the plans have a small piece of tube that "fits" into the center bearing for the elevator attachment and a #30 drill bit fits in the middle that is used to drill the pilot hole before using the step drill. Followed plans but I used emery cloth and my power drill to reduce the diameter of the tube to fit snug into the bearing and then the drill drill to final drill the center of the tube to take the drill bit. Next I stepped drilled the hole to its final size.

This is kind of a pain because I kept dropping the washers, but in the end I needed required washers plus 1 of the thin spacer washers per side.

Done and O so pretty

Looking good!

My original plan was to step up the hole size and final drill it with the reamer, but I didn't have the clearances with the drill to get straight on the holes.

The vertical and horizontal stabs are on.

Boom rudder is on! This is a little tricky by yourself but it can be done with some tape to hold as a third hand

Rudder looks good, Still planning to rebuild it, but Ill fly with this one first and rebuild before I paint I think?

Checking the rudder clearances, all good.

This kit besides the fairing tips is done!! Just got the bill of lading for the fuselage kit so perfect timing I would say. Photo shoot time!!

Using my new toy to check the degrees of deflection to make sure I have a full range of motion. I did have trouble with the elevator leading edges rubbing on both right and left. I had in take them off message the leading edge shape and re-install a few times before it was right.

I didn't get a picture of it but the plans have a small piece of tube that "fits" into the center bearing for the elevator attachment and a #30 drill bit fits in the middle that is used to drill the pilot hole before using the step drill. Followed plans but I used emery cloth and my power drill to reduce the diameter of the tube to fit snug into the bearing and then the drill drill to final drill the center of the tube to take the drill bit. Next I stepped drilled the hole to its final size.

Time in install the elevators and figure out which combination of washers works!

This is kind of a pain because I kept dropping the washers, but in the end I needed required washers plus 1 of the thin spacer washers per side.

Done and O so pretty

Looking good!

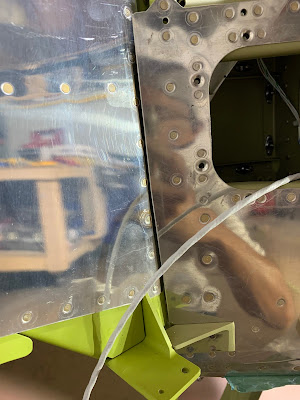

On to mounting and final drilling the horizontal stab. I had to pull the elevators back off to do this. You final drill the top and bottom holes on each side.

My original plan was to step up the hole size and final drill it with the reamer, but I didn't have the clearances with the drill to get straight on the holes.

I bought and angle drill but it was too big and bulky so I had to go with long drill bits, I still tried to step up the hole size and finish with the reamer. This worked, but Im gonna need to invest in a tight space angle drill I think.

Thats on and drilled, now I put the Vertical Stab back on and mock up the rudder and the elevators, again, to check final clearances.

Installing the rudder rod end bearings. I used my small ruler and micrometer to get the distances correct here again.

The vertical and horizontal stabs are on.

Boom rudder is on! This is a little tricky by yourself but it can be done with some tape to hold as a third hand

Rudder looks good, Still planning to rebuild it, but Ill fly with this one first and rebuild before I paint I think?

This kit besides the fairing tips is done!! Just got the bill of lading for the fuselage kit so perfect timing I would say. Photo shoot time!!

Attachment 8.0 Hours

Aft Fuselage

RV 14 Build September 13 & 17

Aft Fuselage

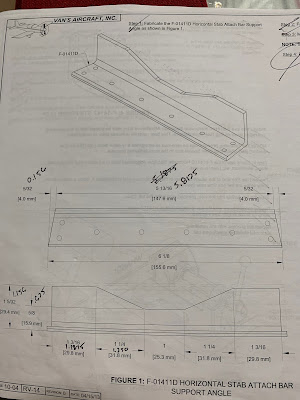

My replacement horizontal stab attach bar support angle showed up and I was able to get it cut, prepped and primed on the first day of work.

This is the plans for the rework.

I have a better understanding of what the angle does and where it sits, it definitely helped in the fabrication knowing how it will be used.

Overall Im happier with this version of the support angle than the first, I did have to go back and hit it with a little more primer after it was done drying I noticed my coverage on part wasnt great.

Getting ready to match drill the hole that I messed up the first time around.

Match drilling successful this time!

Pretending to rivet for the Camera lol

Done! And this completes Section 10: Aft Fuselage

This is the plans for the rework.

Overall Im happier with this version of the support angle than the first, I did have to go back and hit it with a little more primer after it was done drying I noticed my coverage on part wasnt great.

Time to work the install!

Getting ready to match drill the hole that I messed up the first time around.

Match drilling successful this time!

Pretending to rivet for the Camera lol

Done! And this completes Section 10: Aft Fuselage

Aft Fuselage Hours 4.0

Thursday, September 12, 2019

Attachment of the Empennage components

RV14 Build September 12

Attachment

Since Im still waiting on a bracket and the next kit I started to mess around with attaching the components today.

Doing this wasn't in the plans yet, but I wanted to see it all together!

Measured the bolt grip length and labeled them, also labeled the bags with the socket size. Should have done this a long time ago.

Vertical stabilizer Mounting plate is installed!

I thought this would be hared to get the rod end bearings close to the correct distance but it was relatively straight forward, the threats move it a lot with 1/2 a turn when you are close so its easy to tell where you should be.

Left Elevator installed on the horizontal Stabilizer!

Doing this wasn't in the plans yet, but I wanted to see it all together!

Measured the bolt grip length and labeled them, also labeled the bags with the socket size. Should have done this a long time ago.

Vertical stabilizer Mounting plate is installed!

Just looks so good!

Installed the trim motor finally, now the Elevator section is technically done!

I thought this would be hared to get the rod end bearings close to the correct distance but it was relatively straight forward, the threats move it a lot with 1/2 a turn when you are close so its easy to tell where you should be.

Left Elevator installed on the horizontal Stabilizer!

Attachment 2.0 Hours

Horizontal Stabilizer mistake repair...AGAIN

RV14 Build September 12

Horizontal Stabilizer

The repair that I thought worked...well didn't. The two holes that I drilled are 3/32 different on there center point. I have no idea how I was so far off. Oh well, plan B it is. Drill out the rear spar, flip it and install it in the correct orientation to the front spar. Then I can use the front spar mounting holes that Vans Drilled.

Time to start drilling rivets!

Got the rear spar out without any damage!

Using a punch to remove the old rivets from the spar since its thick.

Its nice that I can use the squeezer to install all these at least

Almost have the top done.

Top is done, just flip and repeat

All the pop rivets are back in and now have to squeeze the last rivets on the inner ribs.

Done and Done! Call the Horizontal Stabilizer section complete....Finally.

Horizontal Stabilizer 3.0 Hours

Subscribe to:

Comments (Atom)

Before Start and First flight testing

R14 Build August & September 21 Testing Getting into the fun stuf!! Putting gas in for the first time. Have the airplane up to get 15 d...

-

RV14 Build May 21 Cowling First thing you need to do is level the airplane. I checked it at several areas but thing the spar is probably the...

-

I got to the shop everyday last week! I feel like I made a ton of progress. I finished the rework of the Vertical Stabiler parts that I had ...

-

RV14 Build August 21 Canopy and Window I waited on the rear window install to make it easier to get in and out of the plane to work. Now th...

-

RV14 Build August & September 21 Empennage Fairing I dont know why but I really didn't ant to work on this. I think the composite i...

-

Rv14 Build June 21 Air Vents The plans have you wait on the air vents till after the panel is in to make sure everything fits correctly. So...

-

RV14 Build May & June 21 Emag wiring and FWF Getting the CHT wired in, had to test it lol! All the CHT are in. I used my heat gun to tes...