RV14 Build July 5 & 6

With the elevators basically done back to work on the aft fuselage! Started out by countersinking the stiffeners. Im having issues with the runout on my Dewalt drill, but the air drill kept chattering with the counter sink, so Im gonna have to find a solution. There is way to much drilling ahead to not be able to do that comfortably.

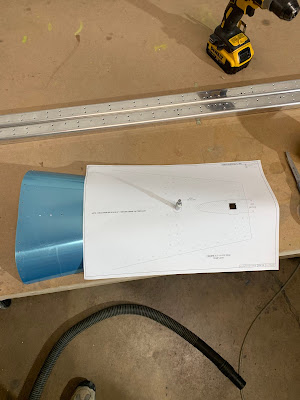

Rear lower skin cutting and drilling with the template. This is done so the tail spring mount can come though the skin.

After the modifications

Testing the tail spring mount clearance. You can see it doesn't sit flush with the rear bulkhead because of the weld bead on the mount. Ill have to cut away from the bulkhead to make room.

Marking where to cut.

Testing the fit after cutting.

Looks great now!

Mixing the primer

Finally done for the day!

Rear lower skin cutting and drilling with the template. This is done so the tail spring mount can come though the skin.

After the modifications

Testing the tail spring mount clearance. You can see it doesn't sit flush with the rear bulkhead because of the weld bead on the mount. Ill have to cut away from the bulkhead to make room.

Marking where to cut.

Testing the fit after cutting.

Looks great now!

Now just cleaning up the edges of the skins, etching the metal and prepping to prime, then priming.

Mixing the primer

Finally done for the day!

Aft Fuselage 10.5 Hours